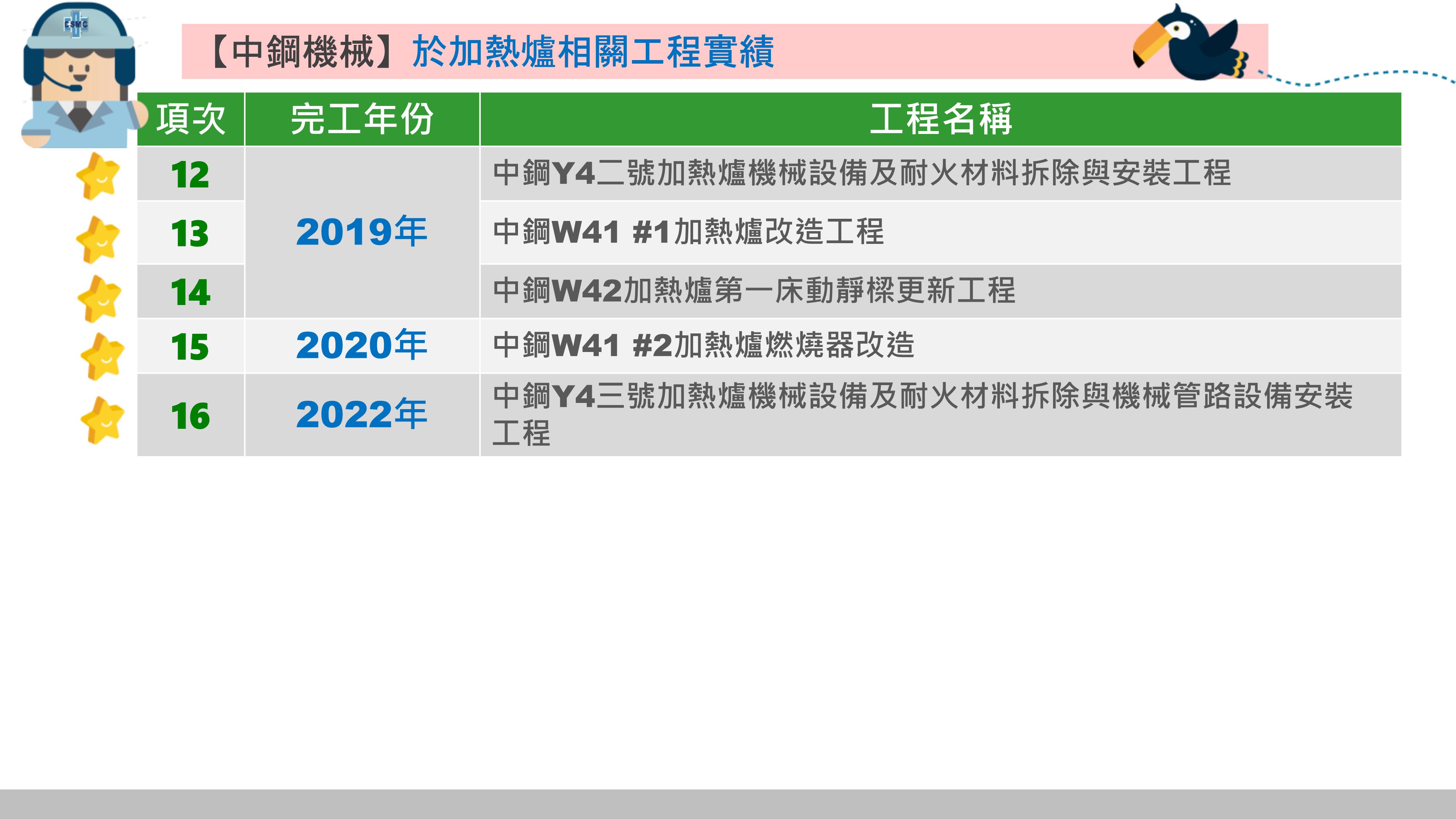

Product description

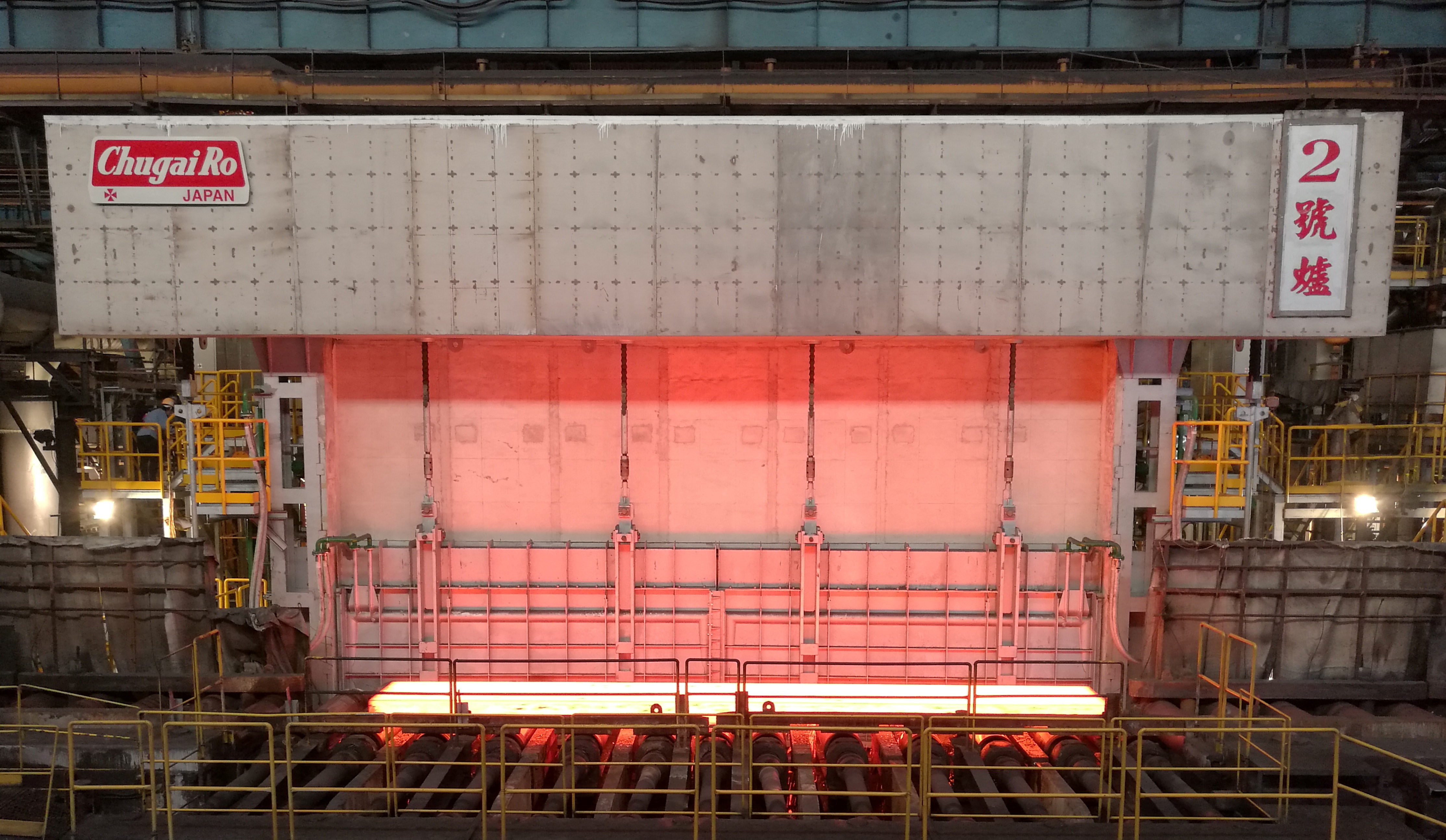

In the hot rolling process, the flat steel billet from the most upstream location enters the heating furnace for heating, and after rough rolling, finishing rolling, cooling and coiling, the steel coils are produced, which are used in downstream production lines or stacked in finished products warehouses. The reheating furnace plays an important role in the hot rolling process. The main purpose is to heat the flat steel billet to 1,250˚C and soften it to facilitate rolling. Therefore, the quality of the steel billet rolling result is deeply affected by the temperature uniformity of the reheating furnace.

China Steel's first hot-rolled steel strip factory reheating furnace was put into operation in 1982, and starting from Jan., 2016 , the three reheating furnaces were renewed. By introducing the latest regenerative reheating furnaces, it can achieve the advantages of enhanced furnace wall insulation effect, good heating efficiency and temperature uniformity, reduced fuel consumption and improved personnel working environment. In addition to increasing the production capacity of the reheating furnaces, the efficiency of the insulation project and the pre-heating system is improved, indirectly reducing pollution emissions, achieving energy saving and carbon reduction.

Project Scope

China Steel Machinery Corporation (CSMC) is in charge of the demolition of old equipment, civil engineering renovation, equipment manufacturing and installation and thermal insulation engineering.

Project completion Date

No. 1 Reheating Furnace completed in 2017;

No. 2 Reheating Furnace completed in 2019;

No. 3 Reheating Furnace project kicked off from Jan. , 2020, scheduled to be completed in July, 2022.

-

CSC Steel Plate Mill Cold Rolling Leveler

Level steel plates and remove the internal stress in steel plates to ensure the precision and quality stability of processing products

-

Dragonsteel converter workshop ladle furnace modification project

This is the Dragonsteel converter workshop ladle furnace (L/F) EPCC modification project. It aims to transform a double-station ladle furnace into two ladle furnaces.