Product description

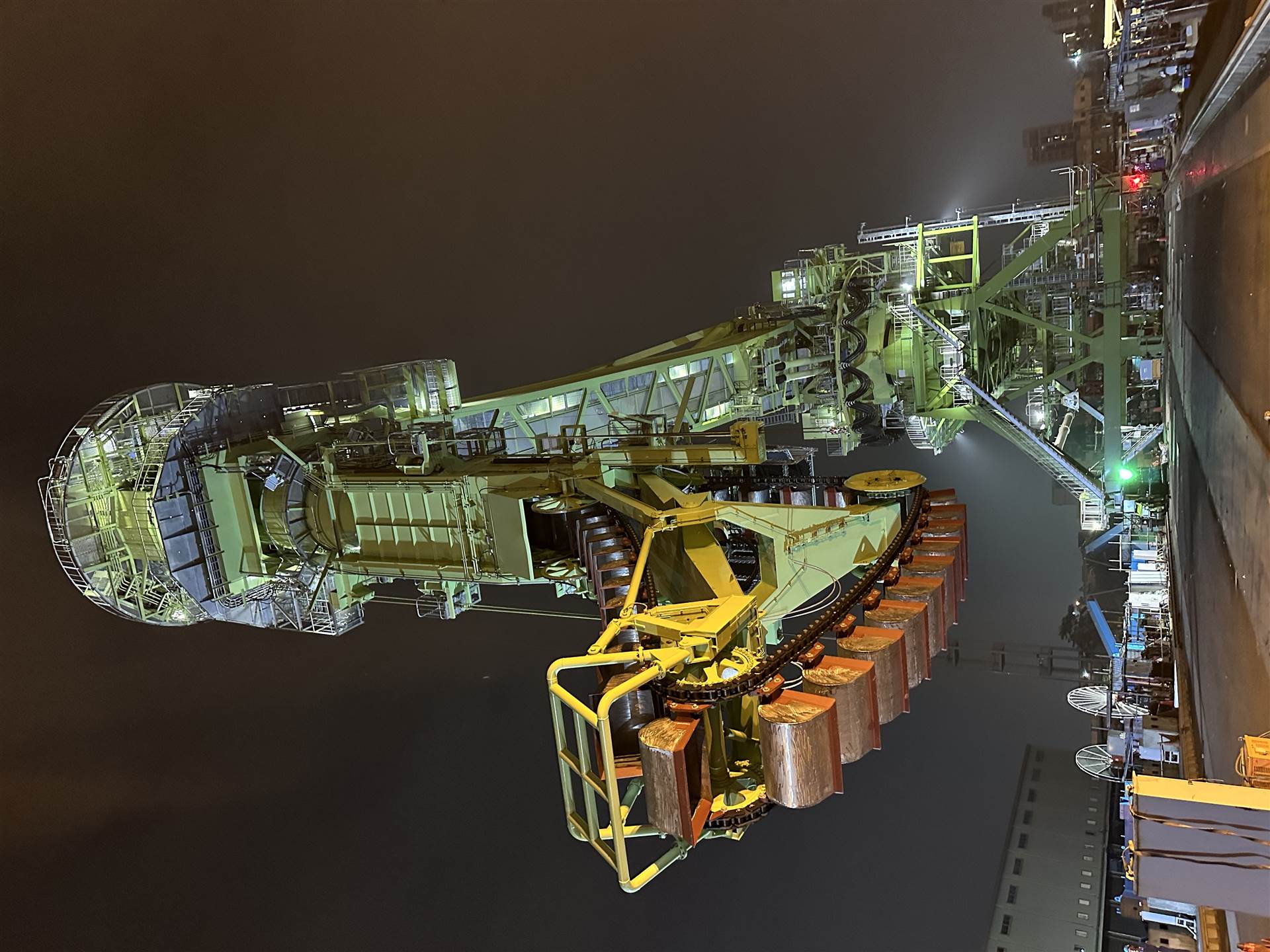

Bucket Elevator Type Continuous Ship Unloader Grabbing raw materials from the cabin (such as: Iron ore, coal mines, stone materials). The enclosed transportation of automatic equipment not only greatly improves the efficiency of ship unloading, but also reduces environmental problems such as ship unloading, dust pollution, oil pollution and noise. Through the conveyor belt system, the raw materials piles are unloaded in the raw materials storage yard. This conveying equipment is widely used in steel mills, power plants, cement industries, etc.

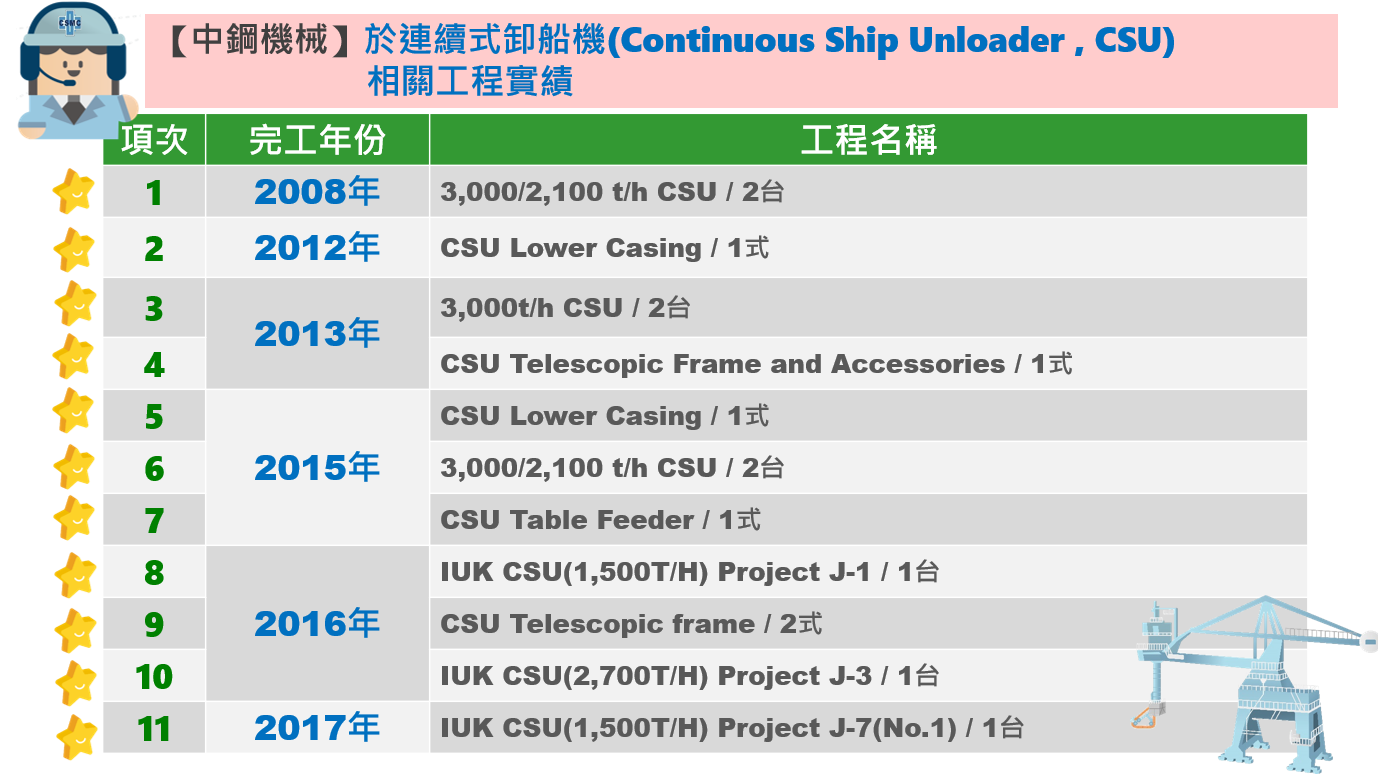

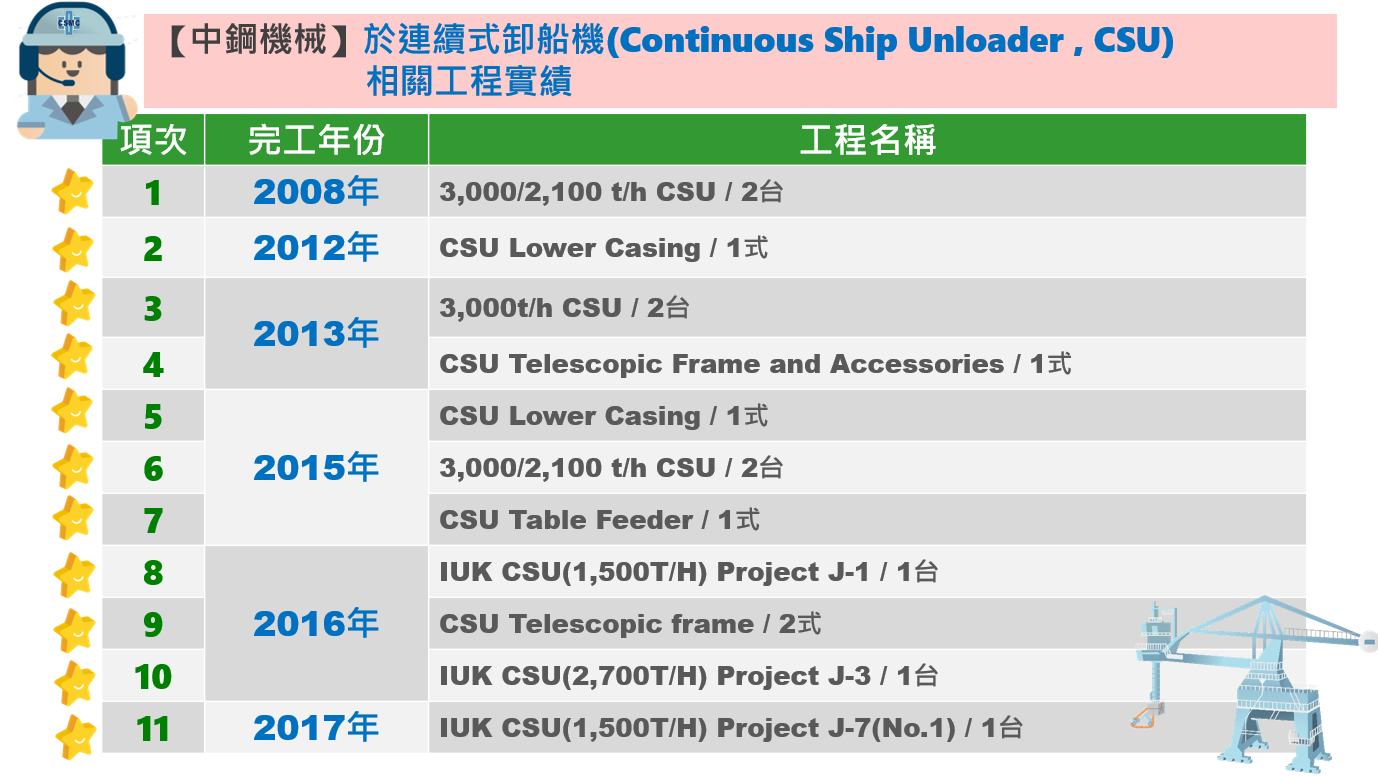

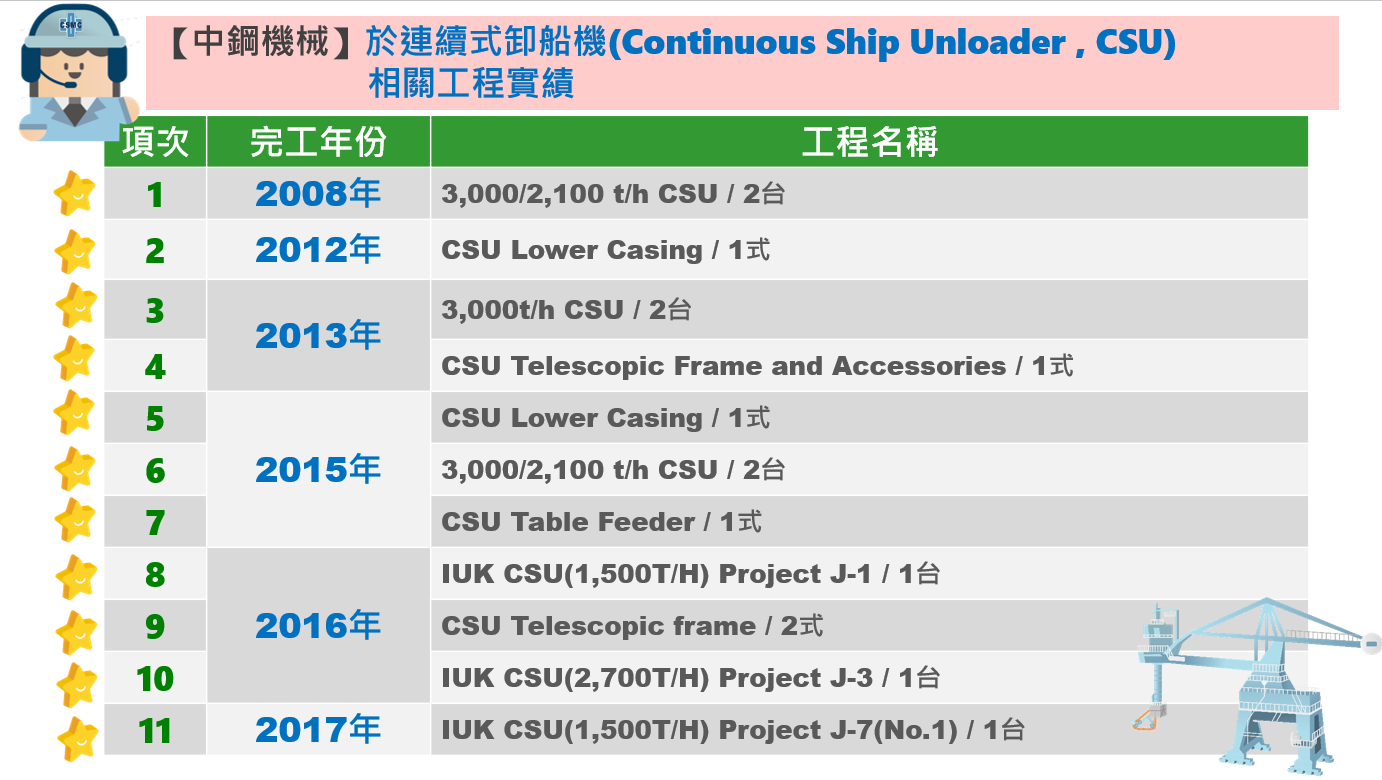

In response to the expansion of the group company Dragon Steel, CSMC entered the field of continuous ship unloader production in 2006, hoping to become an important supplier of international heavy machinery equipment and strive to implement the quality policy of "Providing Customer with Satisfactory Products" gathering abundant manufacturing energy, developing the advantage of being able to assemble and test a complete set of equipment at the backline of the wharf, shipping the finished product directly for export and providing a stable supply of foreign continuous ship unloader equipment.