The blast furnace is the core of the iron and steel plant. It mainly uses conveyor belts to transport iron ore, coke and other raw materials in the silo, which are added to the furnace from the top of the blast furnace and high-temperature hot air is blown from the blast nozzle at the bottom of the furnace to generate reducing gas and reducing iron. The ore produces molten iron and is stored in a torpedo car, which is transported to the steel plant for the next process of steel making.

CSMC is the largest steel equipment manufacturing company in Taiwan and continues to undertake the overhaul and renewal projects of China Steel/Dragon Steel blast furnaces to extend the service life of the blast furnaces.

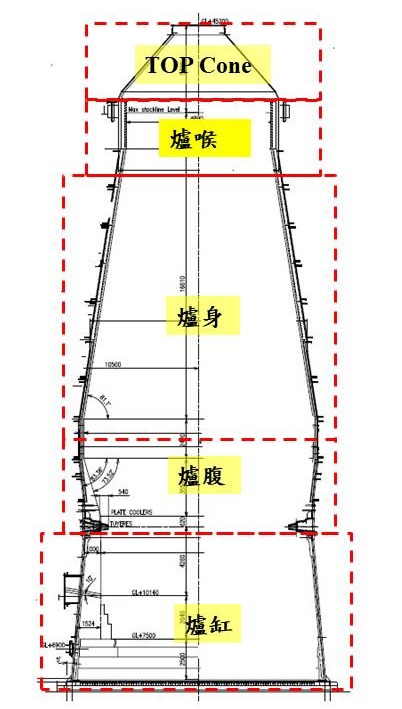

Before the dismantling of the blast furnace body, water injection and cooling related works must be carried out, and the furnace shell opening and related pre-work shall be carried out at the tapping hole; after the furnace excavation operation is completed, the furnace body will begin to gradually remove the furnace shell from the Top Cone. After the dismantling operation is completed, the furnace shell is installed. Before the installation, the necessary furnace shell production and related pre-assembly operations must be completed. The hearth cylinder and hearth belly adopt the bulk furnace shell pushing method, and the furnace shell of the furnace body is installed with the traditional method. After the furnace body and furnace shell are installed, the cooling stave is installed and the Top Cone is installed and positioned and the blast furnace generation update is completed.