Design & R&D

DESIGN FUNCTIONS & DUTIES

-

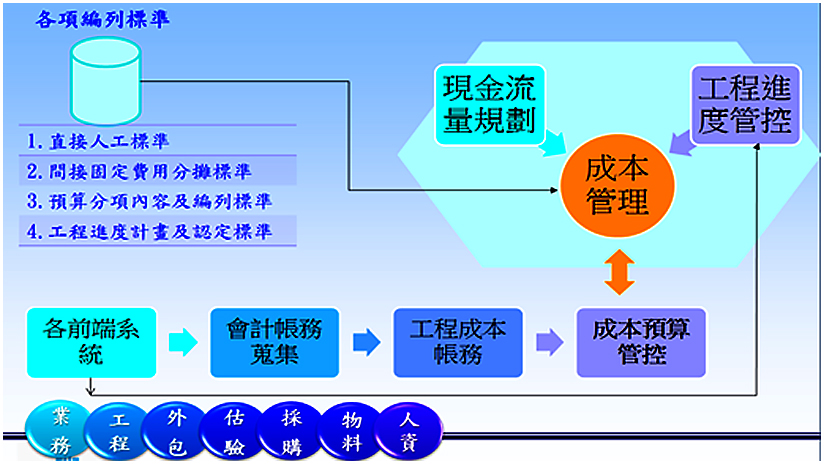

Technology Integration

- Overall Project Planning

- Design Interface Management

- System Performance Collocation Analysis

- Performance Testing and Functional Verification

-

Technology Cooperation

- Technical Cooperation at Home and Abroad

- Introduction of Advanced Design Technology

-

Technical Services

- Engineering Service

- Failure Analysis

- Process Operation Analysis and Improvement

-

Research and Development

- Design and Development of Key Components

- Research and Development of Production Technology

- Computer-aided Stress Analysis

- Design Patent Application

-

Certificates and Standards

- Certificate of Type Inspection for Manufacturing Facilities

- International Standard Quality System Certification

-

Planning, Design and Verification

- Overall Planning of Design Projects

- Equipment Basic Design and Detail Design

- Design Stage Review

- Design Performance Verification